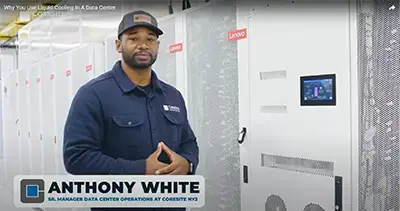

Why Use Liquid Cooling in a Data Center

Nowadays, customer density requirements are higher than ever. That demand calls for more innovative cooling solutions such as liquid cooling. In one of our customer’s suites (shown in this video), we've deployed a CDU, or “cooling distribution unit,” part of a larger liquid coolant solution.

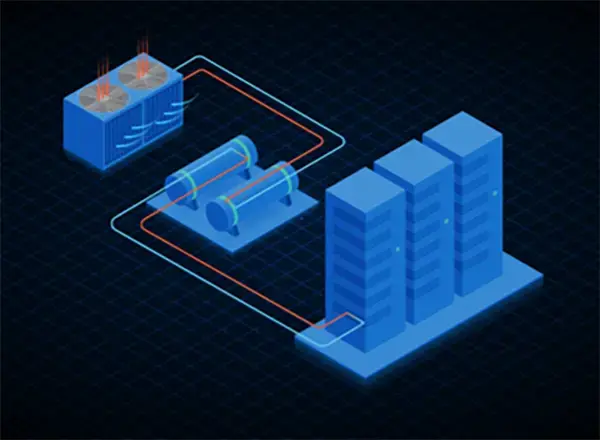

Stage one of the heat transfer process is the only stage that differs between liquid cooling and air-cooled solutions. Unlike traditional methods of removing heat from equipment using air, this solution uses distilled water. That distilled water is pumped through tubes directly to the internal components of each device from which heat is transferred. The warmer distilled water returns back to the cooling and distribution unit, where heat is then transferred from the returned distilled water to water in the chiller.

CoreSite often refers to its data centers as “purpose-built.” On a macro scale, that means designing and operating facilities capable of enabling the applications and interconnection needs of our clients today and anticipating the next waves of infrastructure innovations, while always remaining cognizant of their business goals.

In regard to the specifics of liquid cooling, it is already common practice for data centers to include a Computer Room Air Handler (CRAH) unit, which is a device within a data center that cools the air circulated using a coil filled with chilled water. The water is supplied to the CRAHs by a chilled water plant, also known as a “chiller.” By pre-installing taps on the coils of the chill water pipes pipes, we can easily customize a deployment for liquid cooling.

One liquid cooling option is to use a rear-door heat exchanger on cabinets, which works much like a car’s radiator. A liquid heat exchanger replaces the back door of the rack. Fans blow hot air from servers through the exchanger, which circulates coolant to conduct heat. Ultimately, the warmed coolant, having done its job, is pumped back to the chiller, and the process restarts.

The Benefits of Liquid Cooling

There are several benefits to deploying a liquid cooling solution. First, the devices are make much less noise. Second, the system's footprint is smaller, because the fans have been removed. Most importantly, we can support high-density compute applications such as artificial intelligence. For example, CoreSite’s data center in the New York campus, NY2, is designed to support up to 17 kW per rack without any cold aisle/hot aisle containment. In comparison, the liquid cooled solution (that you will see when you check out the video) is effectively cooling racks that are pulling 65 kW per rack.

According to Data Center Frontier, other benefits include1:

- CPUs and GPUs operate faster and more efficiently

- Reduced energy consumption

- Long-term cost savings in terms of energy consumption and maintenance

Why Liquid Cooling is Becoming Important

At the top of this post, we mentioned that customer density requirements are higher than ever. However, cooling methods have been part of data centers for decades. For example, in the 1960s, IBM implemented liquid cooling for its Systems/360 enterprise-grade mainframes.2

The mainframes of yesterday have given way (for the most part) to radically smaller, radically more dense servers powered by much more energy-intensive CPU and GPU chips. According to AFCOM’s 2024 State of the Data Center Report, “In 2021, respondents reported an estimated mean rack density of 7 kW in their primary data centers. Last year [2023], the average was 8.5 kW/rack. Today, the estimated average has jumped to 12 kW per rack. And most respondents (55%) expect a further increase in rack density over the next 12-36 months.”3

Know More

Go to the CoreSite YouTube channel to see the video Why Use Liquid Cooling in a Data Center that is the inspiration for this blog as well as our entire series of short videos on optimizing your data center deployment.

When you are ready, contact CoreSite to learn more about how CoreSite’s support for modern workloads and digital ecosystem interconnection can help future-proof your enterprise and establish a competitive advantage.

References

1. The Advantages of Liquid Cooling, Data Center Frontier (source)2. An introduction to liquid cooling in the data center, Data Center Dynamics (source)

3. 2024 State of the Data Center Report: How Power Design and AI Demand Has Forever Changed the Industry (source)